芯棒设备

- -产品

- -芯棒设备

-

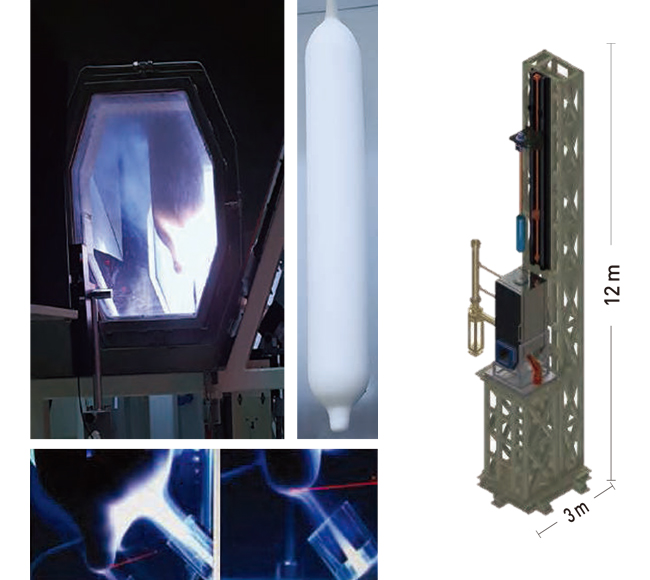

CORE DEPOSITION (VAD)SYSTEM

model : STM - CDV - A150

-

-

描述

The design characteristic of the Core Deposition system is that it uses the VAD method suitable for the production of the LWPF and ZWPF optic fibers. Also, it is the equipment with the superior base material production capabilities. It consists of the vertical lathe that enables the transfer of base material in the vertical direction, the heat-resistant and corrosion-resistant deposition chamber that enables the stable deposition, high-efficiency deposition torch(quartz), high-purity gas and chemical feeder, and exhauster maintaining the static pressure. Its operation applies the PC input/output GUI to facilitate the recipe editing, and it also applies the Siemens motion & drive, ensuring its long-term reliability. It consists of the auto-control system that enables the unmanned operation.

特征

- Low pruduction costs

- High quality preform[for LWPF, ZWPF)

- OH free, Bubble free

- High deposition rate

specification

< 返回主要产品VAD Core System Items Spec(nominal) Remarks Machine Dim 5m x 5m x 12m Machine (WT) 8 Ton Soot Preform (OD) Ø235 ± 15 mm Q.G (Ø100 ± 10 mm) Soot Preform (TL) 1,570 ± 100 mm MAX 15 kg Soot Preform (WT) 13 ± 1 kg U.W (9.2 ± 0.5kg) Deposition Rate 15 ± 1g/min Number of Torch 2 Chemical & Gases SiCl4, GeCl4, CF4, H2, 02, N2 Power (Total) 80 Kw Clean Class # 10,000 Capa (fkm / Machine) 4,200 Capa (Mfkm / year) 2.1 365 day -

-

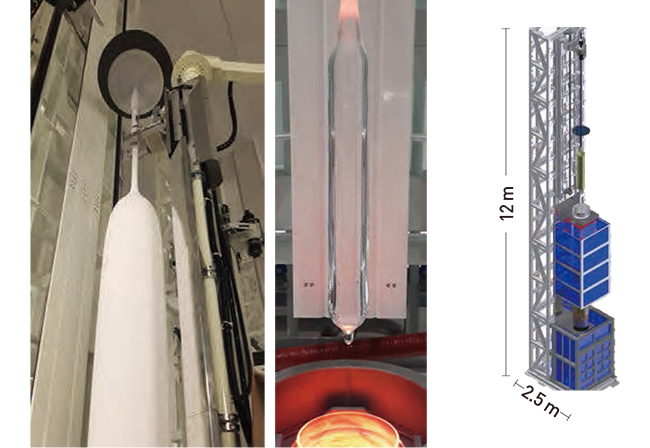

CORE SINTERING SYSTEM

model : STM - CST - A150

-

-

描述

The design characteristic of the Core sintering system is that it enables the heat treatment of the porous white core preform at 1000℃~1600℃, and also the consolidation to obtain the trans-parent and high-quality preform. The 2 furnaces (Z1/Z2) are mounted on the front of the frame for dehydration and consolidation respectively, and the high-quality quartz muffle tube is mounted inside the furnace. It is made up of the process gas device that enables the MFC control at the bottom of the muffle, and heat/chemical exhauster at the top of the muffle. The base material is transferred by the vertical precision bed, and rotated by the top chuck. Its operation applies the PC input/output GUI to facilitate the recipe editing, and it also applies the Siemens motion & drive, ensuring its long-term reliability. It consists of the auto-control system that enables the unmanned operation.

特征

- Low production costs(He, Cl2 gases)

- High quality preform(OH, Bubble free)

- Heater long life time(fixed type)

- High Temp Control(Accuracy, Stability)

specification

< 返回主要产品Core Sintering System Items Spec(nominal) Remarks Machine Dim 3m x 3m x 12.5m Machine (WT) 8 Ton Muffle tube (ID) 300 mm Core(OD) (100 ± 10 mm) Muffle tube (TL) 4,000 mm Core Preform (WT) 13 ± 1 kg MAX 15 kg Furnace Temp 1200 ℃ ~ 1600 ℃ Gases He, Cl2, O2, N2 Power (Total) 130 Kw *UPS Clean Class # 10,000 Capa (fkm/Machine) 4,200 Capa (Mfkm/year) 3.0 365 day -

-

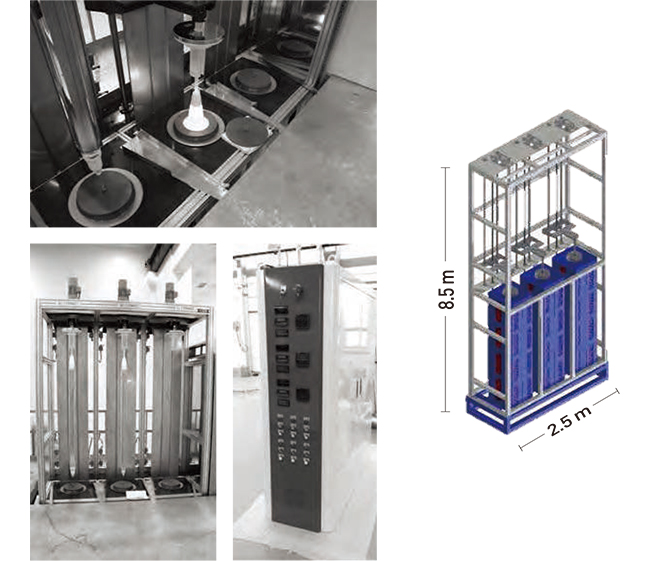

CORE SOAKING SYSTEM

model : STM - CSK - A150

-

-

描述

The major 特征 of Core Soaking System lies in removal of internal stress of core preform to increase core characteristics, which consists of Furnace Quartz Muffle Tube, Up-Down Moving System of Preform, Frame, Preform Hanging Part, and Gas Supply System. With adoption of Kanthal Heater, it uses heat generation design for maintaining around 1100℃ degree to reliance and long durability. Furnace System adopts stable Kanthal A1 Heater and consists of 3 Muffle Tubes and a Furnace. Thermocouple applies RR type to assure reliability of temp sensing. Core preform is fixed by moving cart at quartz holder and its conveyance is performed with precise and steady speed by a motor to prevent shaking of preform. Length of the Muffle is over 2.4 m big enough to soak core preform of over 1.5 m.

特征

- High quality preform(stress free)

- Not used Gases

- Heater long life time(fixed type)

- High Temp Control(Accuracy, Stability)

specification

< 返回主要产品Core Soaking System Items Spec(nominal) Remarks Machine Dim 4 m x 2 m x 8.5 m Machine WT 2 Ton Muffle Tube (ID) 174 mm Core(D) (100 ± 10 mm) Muffle Tube (TL) 2,200 mm Core Preform (WT) 13 ± 1 kg MAX 15 kg Furnace Temp Max 1200 ℃ Power (Total) 100 Kw Clean Class # 10,000 Capa (fkm / Machine) 8,400 Capa (Mfkm/year) 6.1 365 day -

-

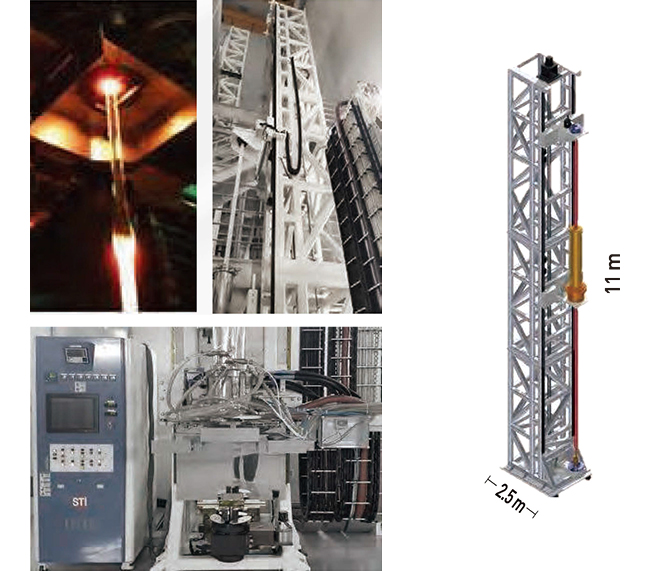

CORE ELONGATION SYSTEM

model : STM - CEG - A150

-

-

描述

- Furnace Body is water-cooled construction made of Stainless steel(316 L)

- Top chamber & shutter should be applied on furnace.

- Heater : High purity graphite resistance (ash contents : less than 10 ppm)

- Furnace inner temp : 2400℃

- N2 gas for inside furnace is flow-controlled.

- Water & Gas inlet pressure : max 6 Bar

- Water flowrate : 150 lpm or more

- Dia measuring

- - Laser scanning type

- - Dia measuring range : Ø3 ~ Ø100mm

- - Measuring Repeatability : within 70㎛

特征

- Chuck(top,bottom) Alignment Accuracy : ±0.05 mm

- High Temp Control(Accuracy, Stability) Range: 1,100 ~ 2,400℃ ±1℃

- Ovality : Max ≤ 0.5 mm

- Bow : Max ≤ 0.5 mm/m

- Tension measurement : 2 Kn

specification

< 返回主要产品Elongation System Items Spec(nominal) Remarks Machine Dim 5m x 5m x 11m Machine WT 8 Ton G. Furnace (ID) 150 mm Core(OD) (100 ± 10mm) After E . Core (OD) Ø40 mm 30~50 mm After E. Core (L) 1,650 mm X 2 pc (TL) 4,500 mm Furnace Temp 2,200℃± 1℃ Gas N2 Cooling Wate 150 lpm Power (Total) 85 Kw Clean Class # 10,000 Capa (fkm/Machine) 4,200 Capa (Mfkm/year) 6.1 365 day -