Clad equipment

- -PRODUCTS

- -Clad equipment

-

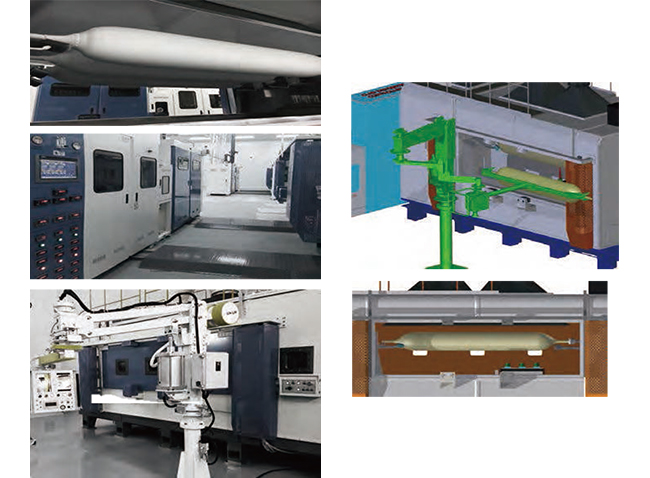

CLAD DEPOSITION (OVD)SYSTEM

model : STM - LDO - A150

-

-

description

Clad Deposition System, with its technology of high quality and productivity, adopts the horizontal OVD (Outside Vapor Deposition) method to realize the lowest cost for optical fiber preform of the same grade. Eventually, it can simultaneously produce 3 preforms per equip with the chamber built by materials for anti-heat and anti-corrosion enabling extended running time of substitution parts and with systems designed for air cooling and process flow in consideration of the characteristics of high capacity of the burner. Chemical and gas flows can be freely controlled by computers for an automatic recipe and cumulative data are recorded in computer to enable analysis and update at any time. Gas cabinet adopts high purity piping(SUS316EP) to allow no factor of contamination and the leaking check of helium gas is done at over 10-9. The recipe is highly advanced equipment epochally improved in consideration of accumulated problems in each step of the process carefully observed by equipping operators.

feature

- Low production Cost (CH4, DR)

- Auto Weight Control(stability_3Spindle)

- Flash Evaporator(repeatability, responsibility)

- CH4 High Deposition Rate Burner(Low Cost)

- High Purity Material Control

specification

< Back To Products MainOVD Clad System Items Spec(nominal) Remarks Machine Dim 6m x 3m x 4m Machine WT 10 Ton Soot Preform (OD) 330 ~ 350 mm Soot Preform (TL) 2650 mm Soot Preform (WT) 72 ± 2 kg with Core Number of Spindle 3 Per Machine Number of Burner 4 Per Spindle Deposition Rate 114 ± 5 g/min Per Machine Gases & Chemical SiCl4, CH4 , O2, N2, Air Power (Total) 95 Kw Clean Class # 10,000 # 10,000 Capa (fkm / Machine) 6,300 Capa (Mfkm / year) 1.62 365 day -

-

CLAD SINTERING SYSTEM

model : STM - LST - A150

-

-

description

The design characteristic of the Clad sintering system is that it enables the heat treatment of the porous white clad preform at 1000 ℃ ~1600 ℃, and also the consolidation to obtain the trans-parent and high-quality preform. The 2 furnaces (Z1/Z2) are mounted on the front of the frame for dehydration and consolidation respectively, and the high-quality quartz muffle tube is mounted inside the furnace. It is made up of the process gas device that enables the MFC control at the bottom of the muffle, and heat/chemical exhauster at the top of the muffle. The base material is transferred by the vertical precision bed, and rotated by the top chuck. Its operation applies the PC input/output GUI to facilitate the recipe editing, and it also applies the Siemens motion & drive, ensuring its long-term reliability. It consists of an auto-control system that enables unmanned operation.

feature

- Low production costs(He, Cl2 gases)

- High quality preform(OH, Bubble free)

- Heater long life time(fixed type)

- High Temp Control(Accuracy, Stability)

specification

< Back To Products MainClad Sintering System Items Spec(nominal) Remarks Machine Dim 3m x 3m x 15m Machine (WT) 8 Ton Muffle Tube (ID) 370 mm preform OD (150 mm ± 4%) Muffle Tube (TL) 5700 mm preform TL (2400 mm ± 5%) Clad Preform (WT) 70 ± 2 kg Furnace Temp 1200 ℃ ~ 1500 ℃ Max 1600 ℃ Gases He, Cl2, O2, N2 Power (Total) 160 Kw *UPS (130) Clean Class # 10,000 # 10,000 Capa (fkm / Machine) 2,100 Capa (Mfkm / year) 1.40 365 day -

-

CLAD SOAKING SYSTEM

model : STM - LSK - A150

-

-

description

Clad Soaking System is equipment with its characteristics of removing internal stress of Clad preform to promote the advantage of Clad, which is composed of Furnace Quartz Muffle Tube, Up-Down Moving System of Preform, Frame, Preform Hanging Part, Gas Supply System. With adoption of excellent Kanthal Heater, it applies a design of heat generation technology for maintaining around 1100C degrees for the long run and durability. Furnace System adopts stable Kanthal A1 Heater and consists of 3 Muffle Tubes and a Furnace. Thermocouple applies RR type to assure reliability of temp sensing. Clad preform is fixed by moving cart at quartz holder and its conveyance is performed with precise and steady speed by a motor to prevent shaking of preform. Length of the Muffle is over 3.0 m big enough to soak Clad preform of over 2.5 m.

feature

- High quality preform(stress free)

- Not used Gases

- Heater long life time(fixed type)

- High Temp Control(Accuracy, Stability)

specification

< Back To Products MainClad Soaking System Items Spec(nominal) Remarks Machine Dim 4m x 2m x 8.5m Machine WT 2 Ton Muffle Tube (ID) 210 mm (L: 2450 mm) Max 250 mm Muffle Tube (TL) 3,000 mm Max 3,500 mm Clad Preform (WT) 70± 2 kg Furnace Temp 1000 ℃ ~ 1100 ℃ Max 1200 ℃ Power (Total) 90 Kw Clean Class # 10,000 # 10,000 Capa (fkm / Machine) 6,300 Capa (Mfkm / year) 3.2 365 day -