Etc

- -PRODUCTS

- -Etc

-

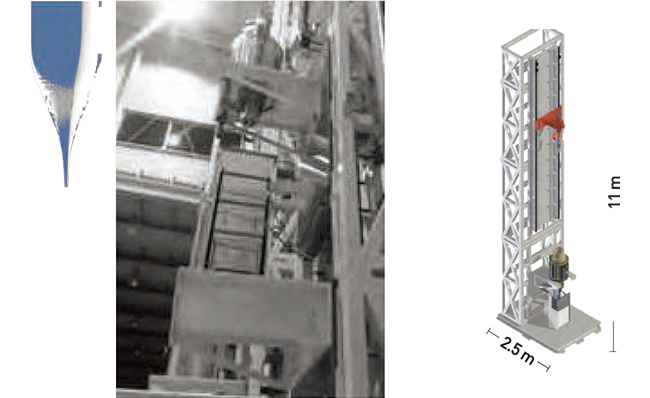

PREFORM SHARPING SYSTEM

model : STM - PSH - A150

-

-

description

The technology is adopted for a Sharpening System in order to save operation time before extrusion of optical fiber. The sinter-treated bottom tip of Preform will be sharpened by free fall in blob melted in the Furnace of 2200C degree high temp. A lift system is equipped at the profile of mainframe to vertically transport Preform. The System consists of a Transformer to supply the furnace with power, a cooling water supply mechanism, and an air gas supply device to prevent the heater from possible damage to furnace.

- Dimension : Body ID Ø 460 * 520

- Furnace temp : 2,150 ℃

- Gases : Ar , N2(max 6 bar)

- Cooling Water : PCW(max 7 Bar)

feature

- High Temp Control(Stability, ±0.1℃)

- Repeatability

- Gas control(MFC Accuracy , 1% FS)

- PC, PLC Auto control

specification

< Back To Products MainSharping System Items Spec(nominal) Remarks Machine Dim 4m x 4m x 11m Machine WT 7 Ton Working Size 130 ~ 160 mm Length: ≤ 2500 ~ 3000mm Furnace Temp ≤ 2200 ℃ Preform (WT) 70 ± 2 kg Cooling Water 100 lpm Gases Ar, N2 Power (Total) 80 Kw Clean Class # 10,000 # 10,000 Capa (Mfkm / year) 5.0 -

-

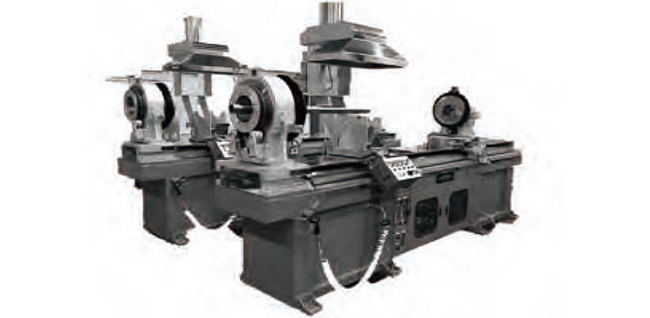

PREFORM MEASURING SYSTEM

model : STM - CRMS - A150

-

-

specification

preform measuring system Items Spec(nominal) Machine Dim 3.5m x 2m x 1.3m Machine WT 0.3 Ton Core diameter ≤ Ø 50 mm Core bow, ovality ≤ Ø 0.1 mm Capa(Mfkm/year) 6.0

model : STM - CMS - A150

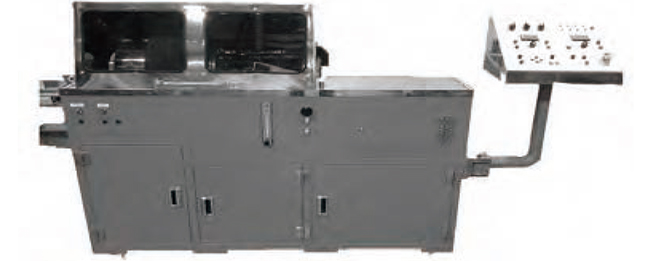

model : STM - LMS - A150

-

-

specification

preform measuring system Items Spec(nominal) Machine Dim 4.5m x 2m x 2.5m Machine WT 0.3 Ton Density (g / cm3) 0.1 ~ 0.9 ± 0.01 g Weight (kg) Max 100 ± 0.01 Kg Capa (Mfkm / year) 6.0

-

-

SICL4 VAPORIZING SYSTEM

-

-

feature

sicl4 vaporizing system Items Spec(nominal) Machine Dim 1.3m x 0.6m x 2.0m Machine WT 0.5 Ton Chemical SiCL4, GeCL4 Flowrate(Max) 5-200 g/min P. Accuracy ≤± 3 torr

FURNACE HEATING CONTROL SYSTEM

-

-

feature

furnace heating control system Items Spec(nominal) Machine Dim 1.5m x 0.6m x 2.1m Machine WT 0.5 Ton Temp Control 800 ℃ ~ 1,600 ℃ T.Accuracy ≤± 1 ℃ Heater Kanthal super

GAS SUPPLY SYSTEM

model : STM - LDF - A150

-

-

feature

- Eesy of operation&maintenance

- Precision MFC Control

- Gases : CH4, O2, N2, Air

- Customized design for specific applications

- Maximizes the safety of an operator

model : STM - LDFN - A150

-

-

feature

- Easy of operation&maintenance

- Ultra high purity : over 8N

- Purification : N2, He, O2, Cl2

- Customized design for specific applications

- Maximizes the safety of an operator

ACCESSORIES

model : STM - WLD - A150

model : STM - CUT - A150

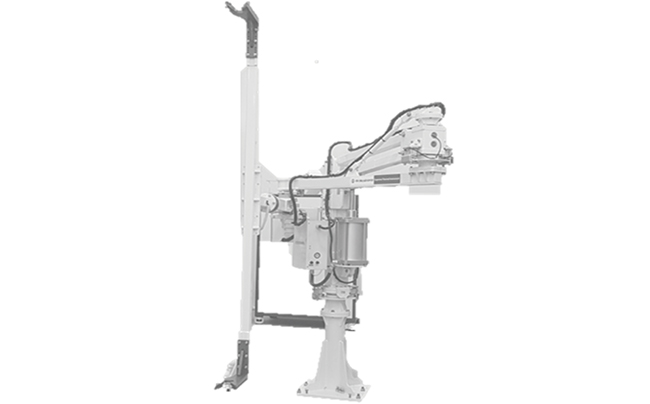

PREFORM MOVING SYSTEM

model : STM - PMS - A150

model : STM - PLS - A150

< Back To Products Main

< Back To Products Main

-